Vanilla extract is a popular ingredient in many Western desserts, adding a distinctive taste and aroma to cakes, ice creams, and other treats. It is traditionally made by steeping vanilla beans in alcohol, which acts as a solvent, extracting the flavor compounds from the beans. While vanilla beans do contain glucose, it is unclear if this is extracted during the alcohol extraction process. Some sources mention the presence of sugars in vanilla beans and their release during extraction, but they do not specify the type of sugar. Other sources claim that vanilla extract does not contain sugar, suggesting that glucose may not be extracted or may be present in trace amounts. Further scientific research on the extraction process and the composition of vanilla extract is needed to confirm whether glucose is extracted from vanilla beans along with other flavor compounds.

| Characteristics | Values |

|---|---|

| Glucose extraction from vanilla beans | Glucose is not directly extracted from vanilla beans during alcohol extraction. However, glucose is present in the reduced sugars released during the extraction process. |

| Alcohol used in extraction | Ethanol, vodka, or other alcoholic beverages |

| Purpose of alcohol | Acts as a solvent to break down cell walls and extract flavor compounds |

| Additional substances | Water is often added to dilute the mixture and create a balanced flavor profile |

| Extraction techniques | Maceration, percolation, cold extraction, and heating methods |

| Number of flavor compounds | Over 300 distinct flavor compounds |

| Main flavor compound | Vanillin |

| Other compounds | Ethylvanillin, p-hydroxybenzaldehyde, p-hydroxybenzoic acid, vanillic acid, and vanillyl alcohol |

| Extraction yield | 82.57% vanillin yield from green vanilla beans |

| FDA regulations | Pure vanilla extract must contain at least 10 g of vanilla beans per 100 ml of extract if beans have <25% water content |

What You'll Learn

- Glucose is a reduced sugar, released during the hydrolysis of cellulosic pod structures

- Alcohol acts as a solvent, breaking down bean cell walls to release flavour compounds

- Water dilutes the mixture, creating a balanced flavour profile

- Vanillin is a key compound in vanilla extract, contributing to its sweet, creamy flavour

- The extraction process involves macerating and percolating vanilla pods in a solution of ethanol and water

Glucose is a reduced sugar, released during the hydrolysis of cellulosic pod structures

Vanilla extract is made by steeping or macerating and percolating vanilla beans in a mixture of alcohol and water. The alcohol acts as a solvent, breaking down the cell walls of the beans and allowing the compounds responsible for the vanilla flavor to dissolve. This process does not extract glucose from the vanilla beans.

Glucose is a simple sugar that is essential for human and animal metabolism. It is a reduced sugar, meaning it has been partially oxidized during the hydrolysis of cellulosic pod structures. This process involves breaking down the complex carbohydrates found in cellulosic materials, such as vanilla beans, into simpler sugars like glucose.

The hydrolysis of cellulosic pod structures is a chemical process that involves the use of acids or enzymes to break down the cellulose into glucose. This process can be carried out through various methods, including acid hydrolysis, enzymatic hydrolysis, and ionic liquefaction followed by post-hydrolysis.

One specific method, described by Chornet et al. in 2010, involves the use of concentrated sulfuric acid to convert lignocellulosic materials into sugars. This process has been patented in the United States and is known as the Concentrated Sulfuric Acid Process. Other variations of this method include using dilute acid for post-hydrolysis and incorporating an enzymatic cellulose hydrolysis step to supply glucose.

The hydrolysis of cellulosic pod structures has the potential to be economically attractive, especially if a minimum acid-to-cellulose ratio is used and a high glucose yield is obtained. However, additional considerations must be made, such as recovering and recycling the used ions and conditioning the final glucose solution for subsequent fermentation.

The Mystery of Native American Alcohol Intolerance

You may want to see also

Alcohol acts as a solvent, breaking down bean cell walls to release flavour compounds

Alcohol is a versatile and widely used solvent for extraction, particularly ethanol. It is used in the laboratory and in industry as a solvent for resins, fats, and oils, and in the manufacture of pharmaceuticals and cosmetics. It is also commonly used in the preparation of medicinal extracts, especially in herbal medicine.

When it comes to vanilla beans, alcohol is used to extract the rich and sweet flavors of the beans, creating an essential ingredient in many Western desserts and baked goods. The alcohol acts as a solvent, breaking down the cell walls of the beans and allowing the compounds responsible for the vanilla flavor to dissolve. This process infuses the flavor compounds into a liquid mixture, resulting in a pure vanilla extract.

The polarity of alcohol enables it to extract a broad range of compounds. It can dissolve both polar and non-polar compounds, making it effective for extracting a wide range of flavor compounds found in herbs, spices, and other botanicals. This is why alcohol is so commonly used in the creation of vanilla extract, as it can effectively capture the more than 300 flavor compounds present in vanilla beans, including the primary flavor compound, vanillin.

Additionally, alcohol has preservative qualities, prolonging the shelf life of extracts. The antibacterial properties of alcohol prevent spoilage and safeguard the integrity of the active compounds in the extract. This is crucial for both culinary and medicinal uses, ensuring the effectiveness and potency of the extract over time.

The use of alcohol in the extraction process also allows for the concentration of flavors without the need for excessive heat. Alcohol's high evaporation rate means that volatile compounds can be captured, resulting in a richer and more robust flavor profile. This is one of the reasons why alcohol-based extracts are favored by chefs and food producers.

Weed vs Alcohol: Which Impairs Driving More?

You may want to see also

Water dilutes the mixture, creating a balanced flavour profile

Vanilla extract is a flavouring solution made by steeping vanilla beans in a mixture of alcohol and water. The alcohol acts as a solvent, breaking down the cell walls of the beans and allowing the compounds responsible for the vanilla flavour to dissolve. The water in the mixture helps to dilute the mixture, creating a balanced flavour profile.

The process of making vanilla extract involves carefully crafting the solution over several weeks. This is done by intermittently soaking and rinsing the beans using precise concentrations of water and alcohol. This proprietary cold extraction process gently draws out the more than 300 flavour compounds found within the vanilla beans, resulting in a rich and complex flavour profile.

The addition of water to the mixture is crucial to achieving the desired balance of flavours. While alcohol is an effective solvent for extracting the aromatic compounds from the beans, it can be too strong and overpowering on its own. The water helps to temper the intensity of the alcohol, ensuring that the final product has a more subtle and well-rounded taste.

The specific proportions of water and alcohol used in the extraction process can vary depending on the desired outcome and the type of vanilla beans being used. For example, Tahitian vanilla beans are known for their delicate, floral, and nutty characteristics, while other species may exhibit smokier and more tar-like flavours. Adjusting the ratio of water to alcohol allows extract producers to highlight specific flavour notes and create unique profiles.

Furthermore, the presence of water in the mixture also contributes to the overall consistency and texture of the final product. By diluting the alcohol, the water helps to create a more fluid and pourable extract, making it easier to measure and incorporate into recipes. This is particularly important for applications where precise measurements and control over the intensity of the vanilla flavour are required, such as in baking or confectionery.

Alcohol Sales on Christmas in New Mexico

You may want to see also

Vanillin is a key compound in vanilla extract, contributing to its sweet, creamy flavour

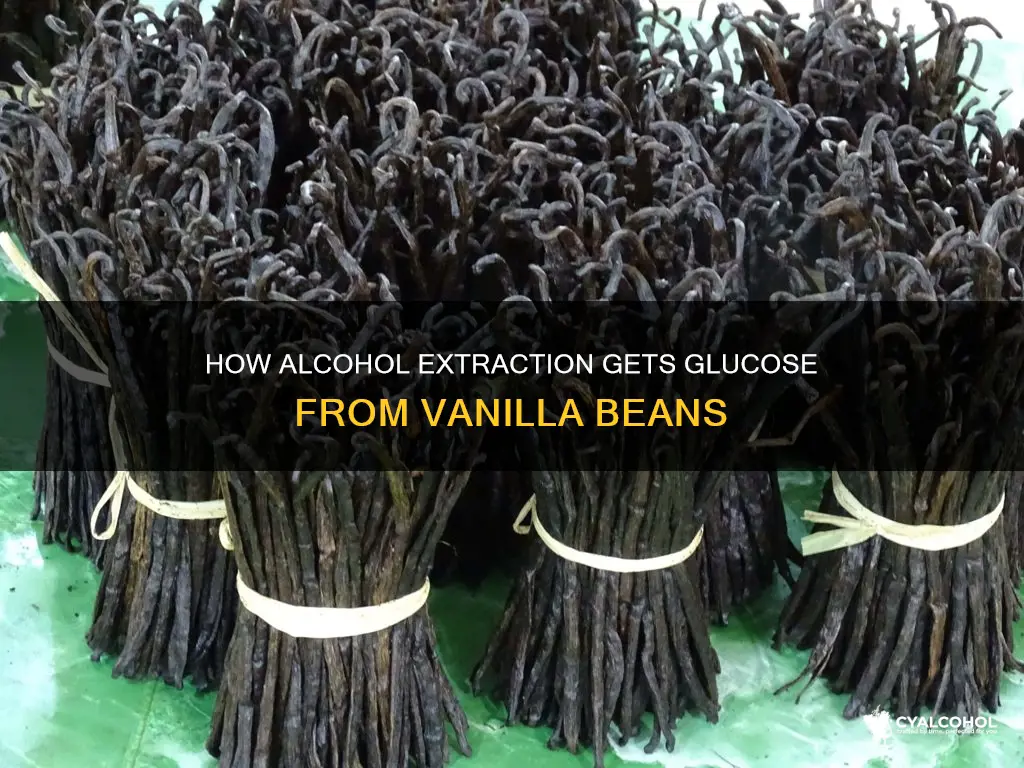

Vanilla extract is a solution made by macerating and percolating vanilla pods in a solution of ethanol and water. It is an essential ingredient in many Western desserts, especially baked goods. Vanilla beans are harvested once a year in every vanilla-producing country except Uganda, which can harvest twice a year due to its two dry seasons.

Vanillin is most prominent as the principal flavour and aroma compound in vanilla. Cured vanilla pods contain about 2% by dry weight of vanillin. It is also found in Leptotes bicolor, a species of orchid native to Paraguay and southern Brazil, and the Southern Chinese red pine. At lower concentrations, vanillin contributes to the flavour and aroma profiles of diverse foodstuffs such as olive oil, butter, raspberry, and lychee fruits.

The largest use of vanillin is as a flavouring, usually in sweet foods. The ice cream and chocolate industries comprise 75% of the market for vanillin as a flavouring, with smaller amounts used in confections and baked goods. Vanillin is also used in the fragrance industry, in perfumes, and to mask unpleasant odours or tastes in medicines, livestock fodder, and cleaning products.

Vanilla extract consists of over 300 flavour compounds aside from vanillin, including acids, ethers, alcohols, acetals, and heterocyclics, which provide subtle nuances. While vanillin alone cannot fully replicate the taste of pure vanilla extract or beans, it is the dominant compound in both natural and artificial vanilla flavouring.

Georgia's Christmas: Alcohol Sales Banned

You may want to see also

The extraction process involves macerating and percolating vanilla pods in a solution of ethanol and water

The process of extracting glucose from vanilla beans involves macerating and percolating vanilla pods in a solution of ethanol and water. This extraction method is commonly known as traditional vanilla extract production, and it is an essential process in creating the familiar vanilla flavour used in many applications.

Vanilla beans are the key starting ingredient in vanilla extract production. These beans are derived from vanilla orchids, which are native to Mexico but now cultivated in many other regions, including Madagascar, Indonesia, and Uganda. The beans are the seedpods of the vanilla orchid and contain the hundreds of flavour compounds that give vanilla its distinctive taste and aroma.

The extraction process begins with the maceration of the vanilla pods. This involves soaking the vanilla beans in a solution of ethanol and water. Ethanol, a type of alcohol, acts as a solvent, breaking down the cell walls of the beans and allowing the flavour compounds to be extracted. The water in the solution helps to dilute the mixture and create a balanced flavour profile. This step can be performed through a proprietary cold extraction process, which gently draws out the flavour compounds, or through a conventional soxhlet extraction method, which uses higher operating temperatures.

Following maceration, the vanilla solution undergoes percolation, where it is carefully filtered to remove any solid particles, leaving behind a pure vanilla extract. This extract is then ready for use in a variety of applications, from baked goods to beverages. The extract is prized for its complex, deep flavour, which comes from the numerous flavour compounds present in the vanilla beans, including vanillin, ethylvanillin, and others.

The extraction process is designed to capture the essence of vanilla beans in a usable liquid form. While glucose is not specifically targeted for extraction, the process does result in a solution that contains a wide range of flavour compounds, including those that contribute to the sweet and creamy notes associated with vanilla. This natural vanilla extract is distinct from artificial vanilla flavouring, which primarily consists of artificially derived vanillin.

Alcohol Wipes: Safe for MacBook Pro?

You may want to see also

Frequently asked questions

No, glucose is not extracted from vanilla beans during alcohol extraction. However, the process does involve extracting the flavour compounds from the beans, which are then infused into a mixture of alcohol and water to create the vanilla extract.

The main compound extracted from vanilla beans is vanillin, which gives vanilla its sweet and creamy flavour. Other compounds include ethylvanillin, p-hydroxybenzaldehyde, p-hydroxybenzoic acid, vanillic acid, and vanillyl alcohol.

Alcohol acts as a solvent, breaking down the cell walls of the vanilla beans and allowing the flavour compounds to dissolve. It also helps to preserve the flavour compounds and can extend the shelf life of the extract.

Yes, there are alternative methods such as cold extraction, which uses natural processes to capture the flavour and aroma of vanilla without alcohol or added sugars. Other alternatives include using vanilla butter, vanilla sugar, or vanilla powder.