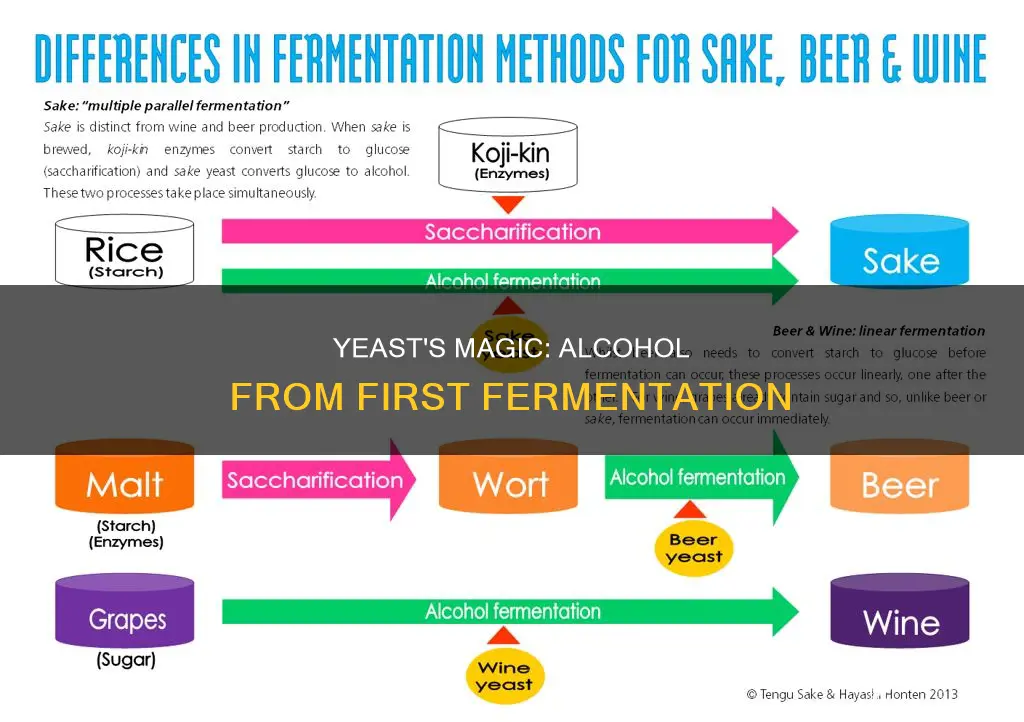

Fermentation is a metabolic process that has been used by humans for thousands of years to produce alcoholic beverages, bread, and other by-products. The process involves the conversion of carbohydrates, such as starch or sugar, into alcohol or acid. Yeast, a single-celled organism, plays a crucial role in this process by consuming sugars and converting them into alcohol. This conversion occurs in the absence of oxygen, making it an anaerobic process. The addition of yeast to a sugar-rich substrate, such as fruit or fruit juice, initiates alcoholic fermentation, resulting in the production of ethanol and carbon dioxide. This process is essential for creating various alcoholic drinks, including beer, wine, and cider, as well as for bread dough rising.

| Characteristics | Values |

|---|---|

| Fermentation Process | Alcoholic Fermentation |

| Fermentation Agent | Yeast |

| Yeast Type | Saccharomyces cerevisiae |

| Yeast Activity | Converts sugars to ethanol and CO2 |

| Fermentation Conditions | Anaerobic (absence of oxygen) |

| Fermentation Time | Several hours to days |

| Fermentation By-Products | Heat, CO2, methanol, fertilizer, etc. |

| Fermentation Applications | Wine, beer, cider, bread, biofuel |

| Fermentation Discovery | Louis Pasteur, 19th century |

What You'll Learn

Yeast must be alive to produce alcohol

Yeast fermentation is one of the oldest human technologies, with its origins dating back to the Neolithic period. Yeast is indispensable for alcoholic fermentation, and it is well established that the most important agent of alcoholic fermentation is S. cerevisiae, a yeast widely used in several fermentation industries, including wine, beer, cider, and bread. Yeast fermentation is not only useful in food manufacturing; its uses extend to other products, such as the generation of fuel from vegetable sources.

Yeast is mostly used as a bio-culture in the alcoholic fermentation process, which involves the breakdown of sugars by yeasts to form pyruvate molecules, also known as glycolysis. Glycolysis of a glucose molecule produces two molecules of pyruvic acid, which are then reduced to two molecules of ethanol and carbon dioxide. This process occurs under anaerobic conditions, where the pyruvate can be transformed into ethanol.

The French chemist Louis Pasteur was the first to demonstrate experimentally that fermented beverages are the result of the action of living yeast transforming glucose into ethanol. He also showed that only microorganisms are capable of converting sugars into alcohol from grape juice and that this process occurs in the absence of oxygen. Pasteur's experiments revealed that fermentation is a vital process, defining it as "respiration without air."

The recognition that yeast is a living entity and not merely an organic residue changed the prevailing idea that fermentation was solely a chemical process. This understanding of yeast as a living organism was confirmed by observations made by French inventor Charles Cagniard de la Tour and independently by Theodor Schwann, Friedrich Kützing, and Christian Erxleben, who concluded that yeast were living organisms.

In summary, yeast must be alive to produce alcohol through the process of fermentation. This knowledge has been instrumental in various industries, including the production of alcoholic beverages, food manufacturing, and the generation of fuel from vegetable sources.

Alcohol in Skincare: Friend or Foe?

You may want to see also

Yeast is used in the production of bread and dough

Yeast is a single-cell microorganism that is part of the fungus family. It is used in the production of bread and dough to perform two main functions. Firstly, as a leavening agent, yeast gives rise to the bread and creates a more open and airy texture. Secondly, it adds strength to the dough, allowing the air bubbles produced to be held in a strong structure. The process by which yeast causes the bread to rise relies on a fermentation process.

The fermentation process involves the enzymes breaking down starches into sugars, which are then converted into carbon dioxide and alcohol by the yeast. The carbon dioxide produced is then held within air bubbles by the elastic gluten network created during the mixing and kneading processes. This is why wheat flour is commonly used in raised bread, as it contains two proteins, glutenin and gliadin, which, when combined with water, form gluten. As the dough is kneaded, the gluten becomes stretchier, allowing it to hold more air bubbles.

The most common type of yeast used in baking is Saccharomyces cerevisiae, also known as baker's yeast. This variety of yeast is specifically adapted for baking and is widely used in the fermentation industry. While the exact origins of yeast in baking are unknown, it is speculated that yeast was first used in Ancient Egypt. Researchers believe that a mixture of flour meal and water was left out longer than usual, causing the natural yeast contaminants in the flour to ferment. This resulted in a lighter and tastier bread compared to the previous hard, flat cakes.

Yeast is available in various forms, with the main difference being moisture content. The choice of yeast depends on the requirements of the recipe and the baker's expertise. For example, dry yeast forms are suitable for longer-term storage, while rapid-rise yeast, a type of instant yeast, is often marketed for use in bread machines due to its faster dissolution and greater carbon dioxide output.

Overall, yeast plays a crucial role in the production of bread and dough, contributing to the desired texture, flavour, and strength of the final product.

Alcohol and Pregnancy: FAS Fatality

You may want to see also

Yeast is used in the production of chemical precursors

Yeast is a key ingredient in the production of chemical precursors. It is used in the fermentation process to convert sugars into ethanol and carbon dioxide. This process, known as alcoholic fermentation, was first demonstrated by French chemist Louis Pasteur in the 19th century. Since then, yeast has been indispensable in the production of alcoholic beverages such as wine, beer, and cider, as well as in the fermentation of dough for bread-making.

In addition to its role in fermentation, yeast is also used in the production of chemical precursors. Yeast extract is a versatile product derived mainly from waste brewer's yeast. It is rich in nucleotides, proteins, amino acids, sugars, and trace elements. Due to its low production cost and abundant supply of raw materials, yeast extract has found applications in various industries. For example, it is used as an animal feed additive, providing a more balanced nutritional supplementation compared to plant-sourced supplements. Yeast extract is also added to dietary supplements to meet human nutritional requirements, especially as a source of B vitamins and fiber.

In the pharmaceutical industry, yeast plays a crucial role in the production of biopharmaceuticals. S. cerevisiae, a common yeast species, is easy to genetically engineer and is used to produce various drugs through metabolic engineering. About 20% of biopharmaceuticals are produced using this yeast, including insulin, vaccines for hepatitis, and human serum albumin. Additionally, yeast has found applications in skincare and cosmetic products. Yeast extract has been shown to effectively degrade and remove melanin from human skin, making it a useful ingredient in skin-lightening formulations.

Furthermore, yeast is employed in the production of biofuels and advanced chemicals. The ability of yeast to ferment xylose and other substrates is of great interest in the biofuel industry, as it helps reduce the environmental cost of efficient biofuel production. Yeast is also being explored in biorefinery processes, where it can be reprogrammed for use in bioprocesses to further enhance the efficiency of chemical production.

The versatility of yeast extends beyond fermentation and chemical precursors. Yeast is an essential ingredient in global food processing, such as coffee and chocolate production. It contributes to the unique flavors and sensory profiles of these products. Additionally, yeast plays a crucial role in wastewater treatment, helping to break down and treat wastewater streams.

Alcohol vs India Ink: What's the Difference?

You may want to see also

Yeast is used in the production of fuel from vegetable sources

Yeast is a key component in the production of fuel from vegetable sources. The process of converting biomass into ethanol is called fermentation, and it is one of the oldest human technologies, dating back to the Neolithic period. During fermentation, microorganisms such as bacteria and yeast metabolize plant sugars and produce ethanol. This process, known as alcoholic fermentation, is carried out by yeasts and some other fungi and bacteria. Yeast breaks down sugars to form pyruvate molecules, which are then converted into ethanol and carbon dioxide.

The most common type of biofuel produced through fermentation is ethanol. Yeast, particularly Saccharomyces cerevisiae, is commonly employed in ethanol production due to its high ethanol productivity, high ethanol tolerance, and ability to ferment a wide range of sugars. First-generation biofuels are made from traditional feedstocks such as cereal grains, sugarcane, and sugar beets, while second-generation biofuels are made from non-food crops and waste biomass. Biodiesel, another type of biofuel, is produced by combining alcohol with vegetable oil, animal fat, or recycled cooking grease. It is a cleaner-burning replacement for petroleum-based diesel fuel and can be blended with petroleum diesel to power diesel engines.

The use of yeast in the production of biofuels offers several benefits. Biofuels have the potential to reduce the transportation sector's carbon footprint and decrease our dependency on fossil fuels. They can also lead to new products or improved versions of traditional petroleum-based products with better performance and lower toxicity. Additionally, smart use of biomass and fermentation through yeast can result in bio-sourced innovations that help mitigate the impacts of climate change and contribute to global carbon neutrality efforts.

The process of yeast fermentation has been optimized over time to improve ethanol production. Various types of yeast strains, including hybrid, recombinant, and wild-type yeasts, have been used in fermentation for ethanol production. However, there are still challenges in yeast fermentation that inhibit ethanol production, such as high temperatures and high ethanol concentrations. Nevertheless, yeast fermentation remains a key enabling technology for a new bio-based and sustainable economy, not just in the fuel industry but across other industries as well.

Alcohol Sales on Christmas in New Mexico

You may want to see also

Yeast is used in the production of beer

Yeast is a tiny, one-celled fungus that is invisible to the naked eye. Yeast fermentation is one of the oldest human technologies, with origins dating back to the Neolithic period. Yeast fermentation is a process where yeast converts carbohydrates (such as starch or sugar) into alcohol or acid. This process is known as alcoholic fermentation. Yeast is indispensable to the process of alcoholic fermentation.

Yeast is essential for the production of beer. The process of making beer involves the fermentation of grains by yeast. The grains from which the wort (liquid obtained from brewing beer) is made are fermented by yeast. The yeast breaks down sugars by converting them into pyruvate molecules, also known as glycolysis. The pyruvate is then decarboxylated to acetaldehyde, which is catalysed by the enzyme pyruvate decarboxylase. The two molecules of pyruvic acid are then reduced to two molecules of ethanol and carbon dioxide.

The type of yeast used in the fermentation process determines the characteristics of the final product. Saccharomyces cerevisiae is the most studied species and the most used in the fermentation of beer due to its rapid growth, easy adaptation, and ability to tolerate high concentrations of SO2. The ability to tolerate different amounts of alcohol varies across different strains of yeast. Brewers can select different strains of yeast to produce different alcohol contents in their beer, which can range from 5% to 21% alcohol by volume.

Yeast fermentation has been used by humans for thousands of years to make alcoholic beverages, as well as bread and by-products. The process of yeast fermentation was first studied by French chemist and microbiologist Louis Pasteur in the 1850s and 1860s. Pasteur experimentally demonstrated that fermented beverages are the result of yeast transforming glucose into ethanol.

Dr. Bob's Story: A Central Tenet of Alcoholics Anonymous

You may want to see also

Frequently asked questions

Alcoholic fermentation, also called ethanol fermentation, is a biological process that converts sugars into alcohol and carbon dioxide. Yeast is responsible for this process, and oxygen is not necessary, making it an anaerobic process.

Yeast performs alcoholic fermentation to obtain energy by converting sugar into alcohol. Yeast can rapidly convert sugars to ethanol and carbon dioxide under both anaerobic and aerobic conditions.

Alcoholic fermentation is used in the production of wine, beer, cider, and bread. Other examples include the ancient Greek practice of fermenting honey and water to produce mead, and the fermentation of grapes to make wine.

The role of yeast in alcoholic fermentation was first studied by French chemist and microbiologist Louis Pasteur in the 1850s and 1860s. He demonstrated that fermented beverages result from the action of living yeast transforming glucose into ethanol.