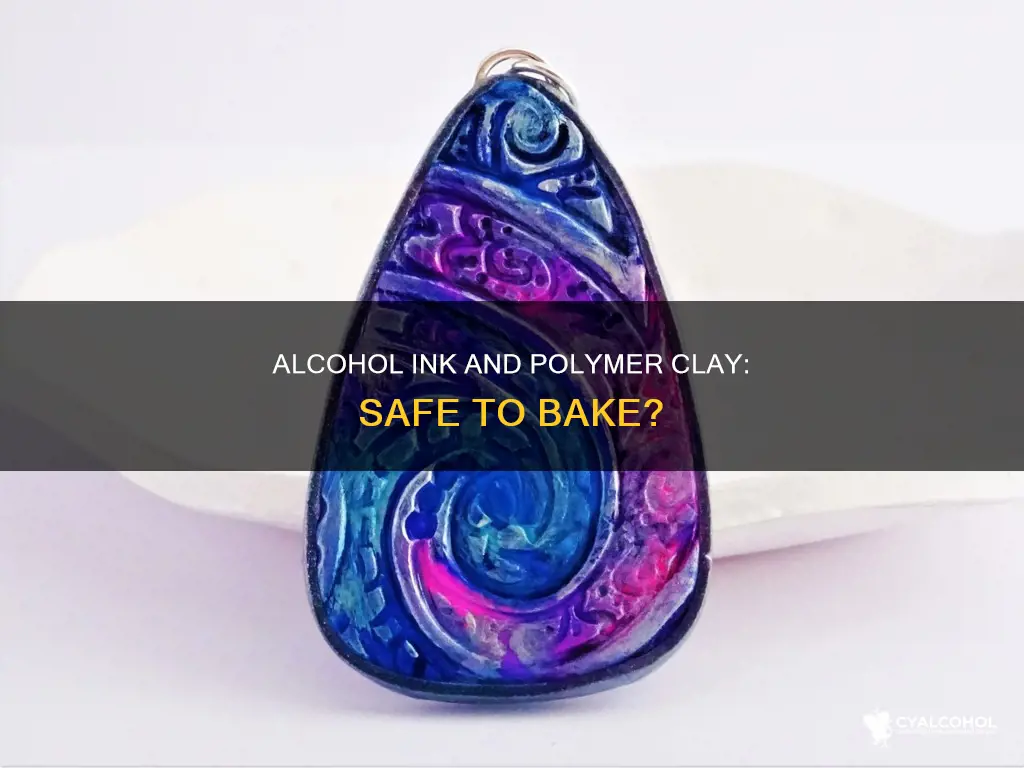

Alcohol ink can be used with polymer clay to create vibrant, intricate designs with rich, translucent colours. Alcohol ink is a dye-based liquid known for its intense colours and fluidity. It can be used on baked or unbaked polymer clay, but it is recommended to work with baked clay to avoid messing up the clay piece. The ink can be applied directly to the clay piece or mixed into the clay itself. The alcohol in the ink evaporates when the ink dries, so it is safe to put in an oven. The temperatures used to bake polymer clay are well below the flashpoint of alcohol. However, it is important to avoid open flames and to store finished products away from direct sunlight and extreme temperatures, as this can fade colours and weaken the clay's structure.

Is alcohol ink safe with polymer clay oven bake?

| Characteristics | Values |

|---|---|

| Safety | It is safe to bake polymer clay with alcohol ink in it. |

| Alcohol content | The alcohol in the ink evaporates when the ink dries. |

| Temperature | Polymer clay bakes at temperatures ranging from 215 to 275 degrees Fahrenheit (102 to 135 degrees Celsius). |

| Application | Alcohol ink can be mixed into polymer clay, applied to unbaked clay, or painted onto baked polymer clay. |

| Results | Alcohol inks give brighter, more concentrated clay colors than other colorants. |

| Versatility | Alcohol inks can be used to create a marbled effect or a uniform color, depending on the desired shade. |

| Storage | Finished products should be stored away from direct sunlight and extreme temperatures to prevent fading and weakening of the clay's structure. |

| Sealant | A compatible sealant can be applied to protect against wear and tear. |

| Cleaning | Alcohol inks can be cleaned with an alcohol blending solution. |

What You'll Learn

Alcohol ink is safe to use with polymer clay

Alcohol ink can be used on polymer clay in three main ways: by mixing it into the clay, applying it to unbaked clay, or painting it onto baked polymer clay. The first method involves adding a few drops of ink in different colours to the clay and gently folding it a few times before rolling it out to achieve a marbled effect. For a uniform colour, the ink can be kneaded into the clay until the desired shade is reached. It is important to note that the ink's colour will compete with the existing clay colour, so choosing a complementary colour is essential.

The second method involves applying alcohol ink to the surface of unbaked polymer clay. This can be done by putting a drop of ink on a felt applicator or directly on the clay piece. The ink can then be spread around, mixed with other colours, or lightened with a blending solution. This method allows for more vibrant and unique colours.

The third method involves painting alcohol ink onto baked polymer clay. This technique is ideal for those who want to avoid messing up their clay piece, as the ink can be easily controlled and manipulated. It is important to note that alcohol ink is more stain-like than paint-like, so creating precise designs, such as polka dots, can be challenging.

When using alcohol ink with polymer clay, it is essential to follow proper safety precautions. Alcohol ink is highly flammable, so it is crucial to avoid open flames and ensure the ink is completely dry before baking. The temperatures used to bake polymer clay are well below the flashpoint of alcohol, so there is no risk of fire as long as the ink is dry. Additionally, it is recommended to wear gloves when working with alcohol ink to prevent staining your fingers.

Combining alcohol ink with polymer clay allows artists to create rich, translucent colours and intricate designs. The low cost of materials and the ease of use make this a great option for those looking to experiment with new art forms.

Alcohol vs India Ink: What's the Difference?

You may want to see also

The alcohol evaporates quickly, so there's no risk of fire

Alcohol ink is a vibrant, dye-based liquid known for its intense colours and fluidity. It is often used with polymer clay to create unique and intricate designs. While it is highly flammable, the alcohol in the ink evaporates quite quickly when the ink dries. This means that as long as the ink is given enough time to dry before baking, there is no risk of fire when curing the clay in the oven.

Polymer clay is a versatile synthetic modelling material that hardens when baked in a home oven. Its composition allows for easy manipulation, blending, and shaping. Polymer clay typically bakes at temperatures ranging from 215 to 275 degrees Fahrenheit (102 to 135 degrees Celsius). The clay's durability post-baking depends on the brand and the thickness of the item, but it generally has a long lifespan if properly cared for.

When using alcohol ink with polymer clay, it is important to consider the unique properties of the clay. Different brands of polymer clay may react differently to alcohol inks, so it is always a good idea to test a process before using it on a large project. The ink can be mixed into the clay, applied to unbaked clay, or painted onto baked polymer clay. It is worth noting that the existing colour of the clay will compete with the colour of the ink.

To create a marbled effect, a few drops of ink in different colours can be added to the clay and gently folded a few times before rolling it out. For a uniform colour, the ink must be kneaded into the clay more extensively. It is also important to ensure that sections are not too thin to prevent brittleness after baking.

In summary, while alcohol ink is flammable, the quick evaporation of alcohol during the drying process eliminates any risk of fire when baking polymer clay in the oven.

Young Adults: Alcohol Dependency Risk Factors

You may want to see also

Polymer clay is baked at a temperature below the flashpoint of alcohol

Polymer clay is a versatile material that can be baked at a wide range of temperatures, depending on the brand and the desired outcome. While the baking temperature can vary, it is important to note that polymer clay should never be baked above certain temperatures to avoid scorching, discoloration, or under-curing. For example, polymer clay should not exceed 275°F (135°C) for any length of heating to prevent under-curing.

The flashpoint of a substance is the lowest temperature at which its vapors will ignite when exposed to an ignition source. Different types of alcohol have varying flashpoints, but they are generally well above the baking temperatures used for polymer clay. For instance, the flashpoint of 99.9% isopropyl alcohol is 53.6°F (12°C), while the autoignition temperature is 399°C (750°F).

When using alcohol inks with polymer clay, it is essential to understand that the inks can be applied in different ways. Alcohol inks can be mixed into the clay, applied to unbaked clay, or painted onto baked polymer clay. The alcohol in the ink evaporates as the ink dries, so it is safe to bake the clay after the ink has dried. However, it is important to avoid open flames when working with alcohol inks, as they are highly flammable.

The baking temperature for polymer clay is well below the flashpoint of alcohol, so there is no risk of combustion during the baking process. Artists and crafters can confidently use alcohol inks with polymer clay and bake their creations without worrying about safety hazards. However, it is always recommended to work in a well-ventilated area and follow safety guidelines when working with any flammable substances.

In summary, polymer clay is baked at temperatures that are significantly lower than the flashpoint of alcohol. This knowledge ensures that artists can safely utilize alcohol inks with polymer clay in their creative endeavors without fear of combustion or other safety concerns.

How Alcohol Travels Through Your Body

You may want to see also

Alcohol ink can be mixed into polymer clay or applied to the surface

Alcohol ink can be used in various ways with polymer clay to create vibrant, intricate designs with rich, translucent colours. It can be mixed into the clay, applied to the surface of unbaked clay, or painted onto baked polymer clay.

When mixing alcohol ink into polymer clay, a few drops of ink in different colours can be added to the clay and gently folded a few times before rolling it out to achieve a marbled effect. For a uniform colour, the ink can be kneaded into the clay more extensively until the desired shade is reached. The colour of the ink will compete with the existing clay colour, so this should be considered when choosing a clay colour.

Alcohol ink can also be applied to the surface of unbaked polymer clay. A drop of alcohol ink can be placed directly on the clay piece and spread around, mixed with other colours, or left to dry for a mottled effect. If the ink dries before you are ready, a blending solution can be added to continue spreading and blending colours.

When using alcohol ink with polymer clay, it is important to note that different brands of clay may react differently to the ink. Additionally, alcohol inks are flammable, so it is important to avoid open flames when working with them. The alcohol in the ink evaporates when the ink dries, so it is safe to bake polymer clay with alcohol ink in an oven. However, it is recommended to let the ink dry before baking.

After baking, proper storage and care are essential to maintain the appearance of the clay piece. Finished products should be stored away from direct sunlight and extreme temperatures, as prolonged exposure can fade colours and weaken the clay's structure. A compatible sealant can be applied to protect against wear and tear, especially for jewellery or frequently handled items. Regular dusting or gentle cleaning with a damp cloth will also help maintain the appearance of the piece.

Alcohol Sales at MSG During Big Ten Tournament

You may want to see also

Alcohol ink is not lightfast and colours may fade over time

Alcohol inks are a vibrant, dye-based liquid known for their intense colours and fluidity. They are often used with polymer clay to create unique designs and colours. However, it is important to note that alcohol inks are not lightfast, and colours may fade over time.

When using alcohol inks with polymer clay, it is essential to consider the potential for fading. Alcohol inks are not lightfast, meaning they will break down and lose their colour when exposed to light, particularly sunlight. This can happen even after the ink has dried and been baked into the clay. To prevent fading, it is recommended to store finished products away from direct sunlight and extreme temperatures. Prolonged exposure to these elements can not only fade colours but also weaken the clay's structure.

Additionally, the application method of the alcohol ink can impact the fading process. When alcohol inks are applied to the surface of baked polymer clay, the colours may be more susceptible to fading compared to when they are mixed directly into the clay before baking. This is because the ink on the surface has not bonded with the clay in the same way as when it is mixed in, making it more vulnerable to the elements.

To minimise fading, it is advisable to use a compatible sealant on the finished product, especially for jewellery or frequently handled items. A sealant will create a protective barrier, reducing the direct impact of light and slowing down the fading process. However, it is essential to test the compatibility of the sealant with the alcohol ink before applying it to the final product to ensure they do not react negatively when combined.

While alcohol inks offer vibrant and customisable colours to polymer clay creations, the potential for fading due to their non-lightfast nature is a factor to consider. Proper storage, the application method, and the use of sealants can help mitigate fading, ensuring that your polymer clay projects maintain their colours for longer.

Alcohol Dependence: Whose Problem Is It Anyway?

You may want to see also

Frequently asked questions

Yes, it is safe to bake polymer clay with alcohol ink. The alcohol in the ink evaporates when the ink dries, and the temperatures used to bake polymer clay are well below the flashpoint of alcohol.

Alcohol ink can be used on baked or unbaked polymer clay. It can be mixed into the clay, applied to the surface of unbaked clay, or painted onto baked polymer clay. To get a marbled effect, add a few drops of ink in different colors to the clay and fold it gently a few times before rolling it out. For a uniform color, knead the ink into the clay until you reach the desired shade.

After baking, allow the clay to cool, then sand the edges of your beads using sandpaper or a polishing cloth. You can then apply a sealant to protect the clay and maintain its appearance. Store finished products away from direct sunlight and extreme temperatures to prevent fading and weakening of the clay's structure.