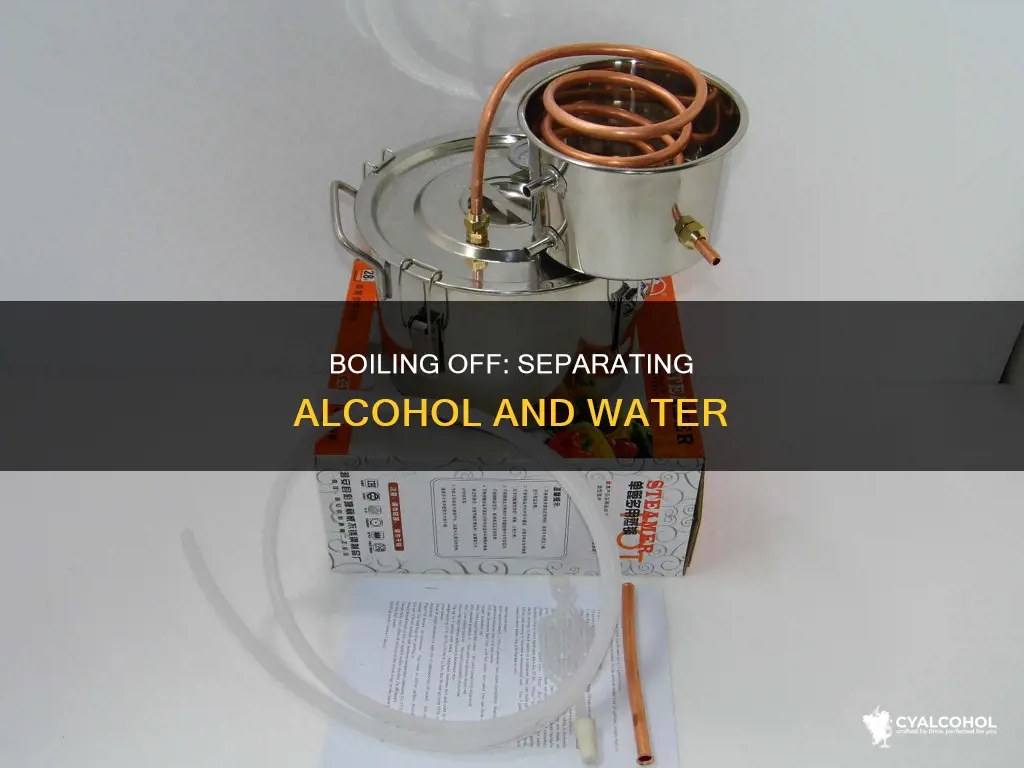

Boiling is a common method used to separate alcohol from water. This is because the two substances have different boiling points, with water's boiling point being 100°C (212°F) and alcohol's being 78°C (172°F). Heating the mixture to 80°C (176°F) will cause the alcohol to evaporate first, and it can then be condensed into a separate container. However, it is important to note that even after extensive heating, a small amount of alcohol will remain in the mixture. This process should be performed with caution and appropriate safety gear, as it involves handling flammable liquids and glassware that can break if heated directly.

| Characteristics | Values |

|---|---|

| Boiling point of water | 100°C (212°F) |

| Boiling point of alcohol | 78°C (172°F) - 78.4°C (173°F) |

| Method | Heat the blended liquid |

| Heat source | Heating mantle, bunsen burner, standard propane or electric heating source |

| Container | Round-bottomed glass flask (boiling flask) |

| Additional equipment | Fractional (fractionating) column, condensing unit, tubing, collection flask, small bags of ice, protective goggles, gloves, long pants, long-sleeved shirt |

| Procedure | Heat the liquid to 80°C (176°F), attach the fractionating column to the flask and connect it to a separate container, collect the condensed alcohol |

| Notes | It is impossible to boil away all the alcohol, even after extensive heating, a small proportion will remain bonded to water molecules |

What You'll Learn

Heating the mixture to 80°C (176°F)

To separate alcohol and water, the mixture must be heated to 80°C (176°F). This temperature is crucial as it is the boiling point of alcohol, which is lower than that of water. By heating the mixture to this specific temperature, you can ensure that the alcohol will evaporate first, turning into steam, while leaving the water behind.

It is important to use a heat source that can quickly raise the temperature to 80°C (176°F). Suitable heat sources include a heating mantle or a Bunsen burner. However, these options may be challenging to control in terms of temperature. Alternatively, a standard propane or electric heat source can be used.

During the heating process, it is essential to use a round-bottomed flask or boiling flask to contain the mixture. This type of flask is recommended because it provides a larger surface area, which facilitates the evaporation of alcohol molecules. Additionally, a fractionating column should be inserted into the mouth of the flask. The fractionating column is typically a straight glass cylinder lined with metal rings or glass/plastic beads. These rings or beads help trap the less volatile gases, ensuring that only the most volatile liquid (in this case, alcohol) rises to the top.

As the mixture reaches 80°C (176°F), carefully monitor the solution for the first signs of boiling. At this temperature, you will observe the alcohol beginning to boil while the water remains liquid. Once boiling occurs, reduce the heat to maintain a gentle simmer. Allow the solution to continue boiling until it stops.

At this point, all of the alcohol will have evaporated and condensed in a separate collection flask, leaving only water behind in the original flask. It is important to allow the apparatus to cool completely before handling the flasks. By following these steps, you can effectively separate alcohol from water by heating the mixture to 80°C (176°F).

Why Alcohol Content Matters

You may want to see also

Using a fractionating column

To separate water and alcohol, fractional distillation is used. This technique relies on the fact that the compounds in the mixture have different boiling points. Since ethanol boils at 78.5°C, whereas water boils at 100°C, the alcohol vaporizes while most of the water remains a liquid. A good distillation column can produce a mixture of 95% alcohol and 5% water, which is widely accepted as the industry standard.

A fractionating column contains a number of plates or trays with holes or caps in them to allow the vapour to pass through. The vapour enters the bottom of the column, rises through the trays, and cools, becoming a liquid that accumulates in the trays. The hottest vapour escapes to the condenser, where it cools and becomes alcohol. However, as the column gets hotter and the trays start to boil, all the liquid will evaporate, and the vapour will rise unobstructed through the neck of each tray, resulting in weak alcohol. An external reflux design can prevent this by keeping the trays flooded with liquid alcohol.

To separate ethanol and water using a fractionating column, the ethanol/water mixture is first poured into a round-bottom flask. The fractionating column is then attached to the flask, with the condenser attached to the top of the column. Finally, a distillate-capturing flask is placed underneath to capture the distillate.

During the distillation process, the ethanol/water mixture is heated, and the ethanol, with its lower boiling point, will evaporate first. The temperature of the column must be controlled so that any water vapour formed condenses in the column and drops back into the flask. This results in the alcohol vapour rising to the top and out into the container, producing pure ethanol. Once all the ethanol has been removed, the solution is heated further to evaporate the remaining water.

Alcoholism and Relationships: Should You Stay or Go?

You may want to see also

Freezing the mixture

To perform this method, place the mixture in a container and put it in a freezer. Once the mixture is frozen, you can remove the solid ice, which will be pure water, leaving the liquid alcohol behind. It is important to note that this method may not completely separate all the alcohol from the water, as some alcohol may be trapped within the ice.

Additionally, the freezing method can be combined with distillation to further purify the alcohol. After the initial freezing and removal of ice, the remaining liquid can be distilled to separate the remaining water from the alcohol. This involves heating the liquid to a temperature between the boiling points of water and alcohol, causing the alcohol to evaporate and condense in a separate container.

Another approach to freezing the mixture involves the use of a water-absorbing desiccant, such as Drierite crystals. These crystals can be added directly to the mixture, where they will absorb the water while leaving the alcohol untouched. The Drierite crystals can then be removed through filtration, leaving pure alcohol behind.

Alcohol Disinfection: How Strong Does It Need to Be?

You may want to see also

Using molecular sieves

Molecular sieves are an effective method for removing water from alcohol and water mixtures. They are synthetic zeolites, which are highly effective at drying hydrocarbons. The process involves passing the ethanol-water mixture through a column filled with the sieve material, which has a strong affinity for water molecules. The water molecules are trapped in the pores of the sieve, allowing pure ethanol to flow past. This method is chemical-free and is the only approved way to maintain food-grade integrity.

The type of molecular sieve used is important. Type 3A molecular sieves are commonly used to dry dehydration solvents. They are effective for ethanol, methanol, and acetone. This is because the pore size of 3A molecular sieves is large enough to allow water molecules (2.8 Å) to enter but small enough to exclude larger solvent molecules. Type 4A molecular sieves, on the other hand, are not suitable for drying ethanol, methanol, or acetone as their pore size does not exclude these solvents.

Molecular sieve beads can absorb water up to 120 °C (250 °F) at atmospheric pressure. To regenerate the beads, they need to be heated above this temperature and/or at lower pressures. The regeneration process should be done carefully to avoid damaging the beads. The regeneration of molecular sieves depends on factors such as temperature, pressure, bead size, and adsorbate concentration.

The process of using molecular sieves for dehydration is relatively straightforward. First, the ethanol-water mixture is passed through a bed of 3A sieve beads under high pressure, activating the molecular sieves. The water molecules are adsorbed by the beads, and the dry ethanol molecules pass through the sieve bed. This process can increase the concentration of ethanol to around 99%.

Overall, molecular sieves are a highly effective and accurate method for removing water from alcohol and water mixtures. They are simple to use and align with health and safety standards, making them a popular choice for producing food-grade ethanol.

Your Wedding, Your Rules: Alcohol-Free Celebrations

You may want to see also

Leaving the mixture to evaporate

As a result, alcohol evaporates more quickly than water. Even after extensive heating, however, a small proportion of alcohol molecules will remain bonded to water molecules in the mixture. The higher the temperature, the quicker the evaporation, and the longer the heating time, the greater the cumulative evaporation.

According to the U.S. Department of Agriculture (USDA), baked or simmered dishes that contain alcohol will retain 40% of the original amount after 15 minutes of cooking, 35% after 30 minutes, and 25% after an hour. Even after 2.5 hours of baking or simmering, 5% of the alcohol content will remain.

The size of the pan also makes a difference: the greater the surface area, the greater the exposure of the alcohol molecules to the air, and the faster they will escape.

It is important to note that leaving the mixture to evaporate may not be the most efficient method for separating alcohol and water. Heating the mixture to a specific temperature and using a distillation apparatus can help ensure a more complete separation of the two substances.

Alcohol Open Carry: Legal in Massachusetts?

You may want to see also

Frequently asked questions

Since alcohol has a lower boiling point than water, it can be separated by heating the blended liquid to 80°C (176°F). The alcohol will evaporate into steam and can be condensed into a separate container.

You will need a distillation apparatus, which includes a round-bottomed glass flask (or boiling flask), a condensing unit, and a second glass container for the separated liquid. A fractionating column can also be inserted between the boiling flask and the condensing unit to improve separation.

Boiling vodka will result in a mixture with a lower water concentration. Eventually, most or all of the alcohol may evaporate, leaving chemically changed products of solids, such as glycerine, trace minerals, and salts.