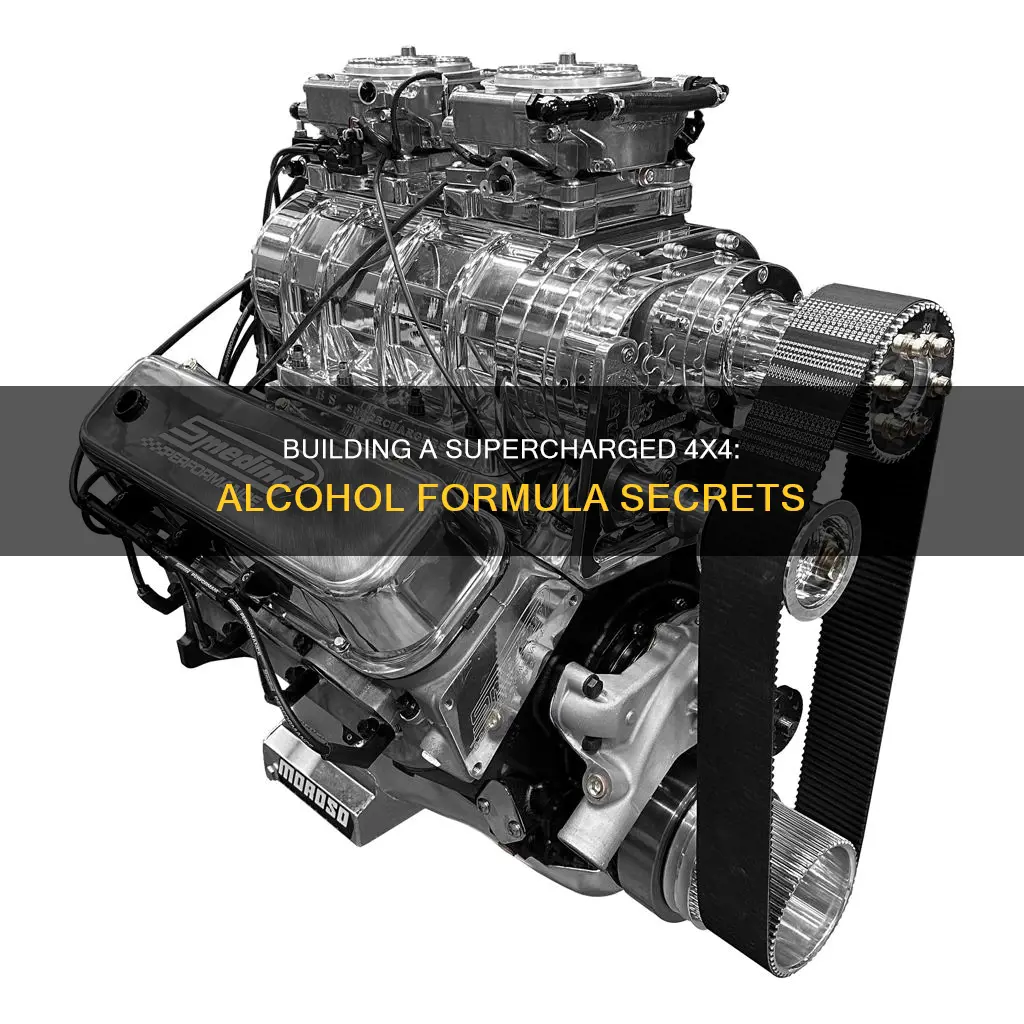

Building a 4x4 supercharged engine that runs on alcohol fuel is a complex task that requires careful planning and execution. The process involves converting a conventional gasoline engine to burn alcohol fuel, which has a higher combustion rate and requires a richer air-fuel ratio. This conversion typically includes modifications to the carburetor, such as enlarging the fuel-metering jets and adjusting the float settings, as alcohol is heavier than gasoline. Additionally, advancing the timing of the ignition system is necessary due to the different burning properties of alcohol. The specific steps may vary depending on the engine's size, compression ratio, and vehicle weight, so it is important to have a thorough understanding of the engine's specifications before beginning the conversion process. While building an alcohol-based engine can be a challenging endeavour, it offers a green alternative to traditional gasoline engines and can be a cost-effective solution in the face of rising gas prices.

| Characteristics | Values |

|---|---|

| Engine type | Single-cylinder |

| Engine displacement | 690-710 mL |

| Supercharger | Yes |

| Fuel type | Alcohol |

| Fuel pump type | Belt-driven |

| Fuel metering jet size | Increase by 40% |

| Float setting | Adjust or purchase a heavier float |

| Timing | Advance |

| Spark plugs | Hotter |

| Compression ratio | Increased |

What You'll Learn

Test parts for compatibility with alcohol-based fuel

When building an alcohol-based engine, it is crucial to test the compatibility of your engine parts with alcohol-based fuel. This process will ensure that your engine can handle the unique characteristics of alcohol fuel and prevent potential damage. Here is a step-by-step guide to testing parts for compatibility:

Firstly, clean the essential components of your engine, including the fuel pump, carburetor, fuel filter, and fuel hose. This step is important as it creates a controlled environment for testing. Once cleaned, these parts should be soaked in at least 180-proof alcohol for an extended period, typically around a month. During this time, carefully observe the parts for any signs of softening, swelling, or other damage. Methanol and ethanol, the most common alcohols used as fuel, can react with certain polymers, causing them to swell and reduce their tensile strength over time.

If you notice any adverse reactions, the affected parts may need to be replaced with ethanol-compatible alternatives. This step is crucial, as using incompatible parts can lead to engine damage and reduced performance. It is worth noting that most modern cars, trucks, and SUVs are designed with ethanol-compatible parts, so you may find that many of your existing components are already compatible with alcohol-based fuel.

Additionally, pay close attention to the carburetor, as it often requires modifications for use with alcohol. You may need a carburetor overhaul kit specifically designed for your carburetor model. This kit will allow you to enlarge the fuel-metering jets and adjust the float settings to accommodate the heavier nature of alcohol fuel.

Finally, it is important to remember that alcohol has a higher octane rating than gasoline, which affects the air-fuel mixture ratio. Experimenting with the orifice sizes (diameters) of the carburetor's main jet can help you find the ideal balance between power and fuel economy.

By following these steps and closely monitoring your engine's performance, you can ensure that your engine parts are compatible with alcohol-based fuel and make any necessary adjustments for optimal performance.

Alcohol on a Plane: What's the Law?

You may want to see also

Modify the carburetor for alcohol fuel

Modifying the carburetor for alcohol fuel is a crucial step in building an alcohol-based engine. Here are the detailed instructions for completing this process:

Firstly, it is important to test your parts to ensure compatibility with alcohol-based fuel. Clean your fuel pump, carburetor, fuel filter, and fuel hose, and then soak them in at least 180-proof alcohol for about a month. Replace any components that show signs of softening or damage due to prolonged exposure to alcohol. This initial step ensures that your engine's components can withstand the unique characteristics of alcohol fuel.

Once you've confirmed compatibility, it's time to remove and disassemble the carburetor. This step requires careful handling as it involves dealing with gaskets, hoses, and other intricate parts. Make sure to have spare gaskets on hand to avoid potential issues with reassembly. Drain out any residual gasoline from the float bowl and locate the main jet, which is typically in the main well support or in front of the float bowl body.

The next step is to enlarge the fuel-metering jets within the carburetor. Use a drill press or a hand drill to carefully increase the size of the jets. The extent of the enlargement depends on the purity of the alcohol fuel you intend to use. Typically, a 20% to 40% increase in size is recommended. This step ensures that the carburetor can deliver the required air/fuel ratio for efficient combustion.

After enlarging the jets, you may need to adjust the float setting or consider purchasing a heavier float. Alcohol fuel is denser than gasoline, so bending the float up slightly or using a new, heavier float will help maintain the proper fuel level. This adjustment is crucial for ensuring the engine receives the correct amount of fuel.

Finally, reassemble the carburetor and fit it back into the engine, ensuring that all connections are secure and proper. It's important to note that you should not drill the jets before removing them from the carburetor, as this can cause shavings to fall into the mechanism and create engine problems.

By following these detailed steps, you will have successfully modified the carburetor to accommodate alcohol fuel, bringing you one step closer to building your alcohol-based supercharged engine.

Alcohol and Citalopram: Is It Safe to Mix?

You may want to see also

Adjust the float setting or purchase a heavier float

Adjusting the float setting or purchasing a heavier float is an important step when building an alcohol engine. This is because alcohol is up to 8% heavier than gasoline, and so the float must be adjusted to maintain the proper fuel level.

To adjust the float, you will need to bend the float up slightly. Alternatively, you can purchase a new, heavier float. This step is part of the process of modifying the carburetor for use with alcohol. Before this, you will need to remove and disassemble the carburetor, and clean the fuel pump, fuel filter, and fuel hose, soaking them in at least 180-proof alcohol for about a month. You will also need to enlarge the fuel-metering jets of the carburetor using a drill press or hand drill, increasing the size by about 40%, depending on the purity of the alcohol.

After adjusting the float, you can reassemble the carburetor and fit it back into the engine. It should connect just as it came out, with no extra or leftover parts. It is important to note that you should never drill the jets before removing them from the carburetor, as shavings could fall into it and create engine problems.

Once the carburetor is reassembled and fitted, you will need to advance the timing of the ignition system, as alcohol burns at a higher rate and takes more time to ignite and vaporize. Finally, test drive your car and make any necessary adjustments to prevent the engine from cutting out or to stop pinging due to poor timing.

Alcohol Ban in South Africa: What's the Story?

You may want to see also

Advance the timing of the ignition system

Advancing the timing of the ignition system in a 4x4 supercharged engine involves making adjustments to the spark plug firing sequence to optimise engine performance. Advancing the ignition timing increases the high-end power of the engine while reducing the low-end power. This process helps overcome ignition delay, ensuring the spark plug fires before the piston reaches the top dead centre (TDC), allowing the air-fuel mixture to fully burn soon after the piston reaches TDC.

To advance the ignition timing, you will need to make adjustments to the ignition system. This typically involves using an advance timing light and a mechanical advance tuning kit. The process can be performed on a chassis dyno for more accurate results, although it can also be done on a street or drag strip. The first step is to tune the engine with the appropriate fuel type and octane rating that will be predominantly used.

The next step is to optimise the base timing, which refers to the position of the distributor in the engine block. This can be done by slowly advancing the timing until peak torque output is achieved. However, it is important to be cautious and slightly retard the timing if the engine starts to knock, ping, or experience minor detonation. This is because excessive ignition advance can lead to engine knocking or detonation, causing potential engine damage.

After optimising the base timing, you can make full-throttle pulls from idle in incremental steps. The first pull should be from idle speed to 3,000 rpm. Subsequently, you can fine-tune the rate of advance to maximise horsepower and torque. This process involves making incremental pulls at increasing engine speeds until the maximum engine speed is reached.

It is important to note that the amount of ignition advance depends on the engine speed and load. Advancing the ignition timing too much can lead to pre-ignition or detonation, especially at low RPMs. On the other hand, if the ignition timing is too retarded, the engine may run flat, produce less power, and overheat. Therefore, finding the optimal ignition timing is crucial to achieving the best performance from your 4x4 supercharged engine.

Empty Alcohol Bottles: Legal to Drive With?

You may want to see also

Obtain the proper licenses for alcohol fuel

To obtain the proper licenses for alcohol fuel, you must first be aware of the relevant laws and regulations. In the United States, the legal framework for alcohol fuel permits is governed by the Alcohol and Tobacco Tax and Trade Bureau (TTB), which is part of the US Department of Treasury. The TTB regulates and oversees distillation processes.

Before initiating the application process, it is essential to understand the different types of permits available and the specific requirements associated with each. The two primary permits to consider are the Federal Distilled Spirits Permit (DSP) and the Fuel Alcohol Plant Permit. The DSP is suitable for those intending to produce ethanol for human consumption, while the Fuel Alcohol Plant Permit is necessary if you plan to use ethanol as a fuel source or as an intermediary for fuel production.

The application process for a fuel alcohol permit typically involves the following steps:

- Ensure that your building and equipment are in place before applying. This allows inspectors to conduct efficient inspections and prevents potential delays.

- Register with the TTB and select the appropriate permit that aligns with your specific use case.

- Complete the application form, providing detailed information about your plant, production methods, and security measures.

- Submit the application to the TTB for review and approval.

- Receive a tracking number to monitor the progress of your application.

- Respond to any correction requests made by the TTB during the processing phase.

- Obtain final approval from the TTB, which signifies that you are fully licensed to begin production.

It is important to note that state laws regarding distillation and alcohol fuel production may vary. While federal law takes precedence, some states have unique regulations governing the ownership of stills and the distillation process. Therefore, it is crucial to research and understand the specific requirements of your state before initiating the permitting process.

Alcoholism and the Fair Housing Act: Is It a Disability?

You may want to see also

Frequently asked questions

You will need mechanic tools, a working gasoline engine, 180+ proof alcohol, a carburetor overhaul kit, a drill press or hand drill, a heavier float, and hotter spark plugs.

First, test your parts to ensure they can work with alcohol-based fuel. Clean your fuel pump, carburetor, fuel filter, and fuel hose, and soak them in at least 180-proof alcohol for about a month. Replace anything that shows damage due to the alcohol. Next, remove and disassemble the carburetor. Enlarge the fuel-metering jets of the carburetor carefully using a drill press or hand drill. Adjust the float setting or purchase a heavier float. Reassemble the carburetor and fit it back into the engine. Advance the timing of the ignition system.

You will need to obtain the proper licenses from the state to make, buy, or store alcohol for fuel, or you could face fines and other legal problems. You'll also need a small amount of gasoline to start the engine in a cold environment, as alcohol won't start at temperatures lower than 60 degrees Fahrenheit.