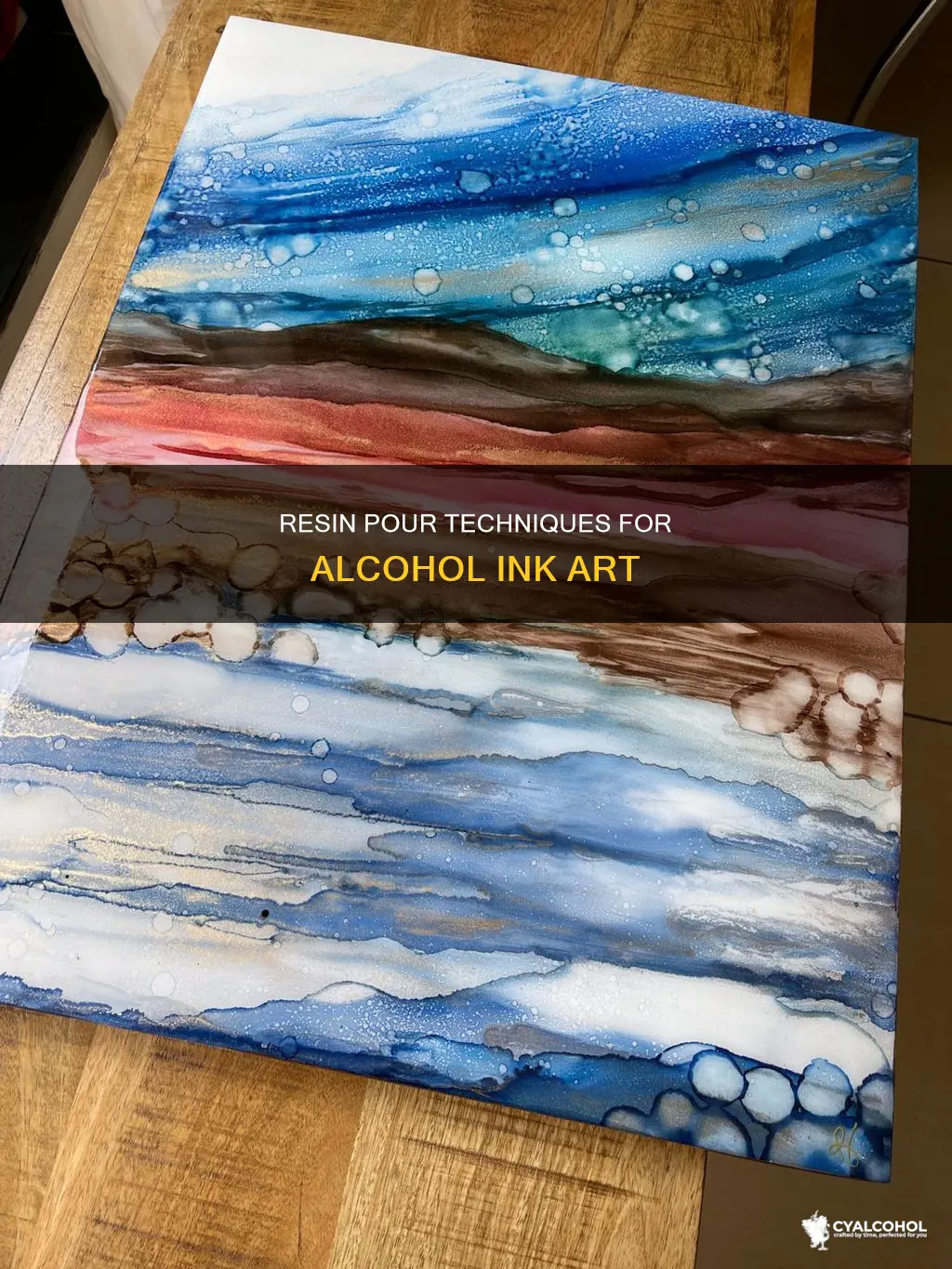

Alcohol inks are a perfect match for resin tinting, and they are often more affordable than resin tints. Alcohol inks are ideal for colouring resin because they are alcohol-based, and the alcohol quickly evaporates, leaving pigment without disrupting the curing of the epoxy resin. When applying resin to alcohol inks, it is important to seal the alcohol ink first. This can be done using Kamar Varnish, a clear-drying spray sealant that prevents the alcohol ink from reactivating, bleeding, or smudging. When pouring the resin, it is important to pour slowly and steadily to control the flow and avoid overfilling. It is also crucial to use accurate measurements to get the resin-to-hardener ratio just right.

What You'll Learn

Preparing your resin

Measuring and Mixing: Start by putting on a pair of gloves to protect your hands. Accurate measurement is essential, so use measuring tools like graduated cups or syringes to ensure you have precisely equal amounts of resin and hardener. For a standard resin mix, maintain a 1:1 ratio. Stir the resin and hardener thoroughly for about 3 minutes, scraping the bottom and sides of your mixing container as you go. You can also add a few drops of white pigment to the resin at this stage if you wish to create a lighter base colour.

Pouring the Resin: After mixing, slowly pour the resin into your chosen mould or directly onto a wood panel. Ensure your surface is clean, dry, and positioned on a level surface to avoid spillage. Pour the resin into the centre, allowing it to naturally flow outwards and fill the space. This technique helps minimise air bubbles. Remember to pour slowly and steadily to control the flow and avoid overfilling.

Guiding the Flow: Use a stick, a toothpick, or a silicone tool to guide the resin into intricate areas or corners that may need extra attention. This step ensures your creation has complete coverage without any missed spots.

Releasing Air Bubbles: Once you have poured the resin, use a heat gun, blow torch, or an artist's torch to gently pass over the surface. Keep the torch moving from side to side, holding it a couple of inches above the resin. This process releases any trapped air bubbles, ensuring a smooth and even finish.

Curing the Resin: Allow the resin to cure and harden. Depending on the type of resin used, this process can take anywhere from a few hours to up to 72 hours. The resin will become tacky and firm to the touch when it is ready for the next step.

Remember, preparing your resin correctly is essential to achieving the desired effects when working with alcohol inks. Always follow safety guidelines and instructions provided by the manufacturers of the specific resin and ink products you are using.

The Angel's Share: Is Grain Alcohol the Answer?

You may want to see also

Preparing your alcohol inks

Choosing the Right Inks

It is important to select alcohol-based inks specifically designed for use with resin. Alcohol inks are ideal for colouring resin because the alcohol base evaporates quickly, leaving behind pure pigment that does not interfere with the curing process of epoxy resin. Avoid water-based inks, as water disrupts the curing process of epoxy resin and can yield undesirable results.

Mixing and Preparing the Inks

Before introducing the ink to the resin, you can mix and prepare your inks to achieve the desired colours and transparency. Using tools like graduated cups or syringes, measure and mix your inks to create custom colours. You can also adjust the transparency by controlling the amount of ink you use. For a translucent effect, start by adding small drops of ink and gradually increase the amount until you achieve the desired vibrancy. If you prefer an opaque, solid colour, add a small amount of non-metallic white pigment powder. This will create a barrier for the ink to bounce off of, resulting in a colour that is not see-through while still allowing light to pass through.

Sealing the Inks (Optional)

If you are applying resin over a wood panel or other absorbent surface, consider sealing your alcohol inks before adding the resin. This step is not mandatory but can help prevent issues like ink reactivation, bleeding, or smudging. A clear-drying spray sealant, such as Kamar Varnish, is commonly used for this purpose. Simply spray it over your alcohol ink art and allow it to dry according to the manufacturer's instructions.

Safety Considerations

When working with alcohol inks and resin, always prioritise safety. Wear gloves and protective eyewear to shield your skin and eyes from potential splashes and fumes. Ensure the work area is well-ventilated to avoid inhaling any harmful vapours.

Timing and Pouring

Once you have prepared your inks and your resin is mixed and ready, it is crucial to work efficiently. Alcohol inks can evaporate, so have your resin prepared and work quickly. Pour the resin into your mould or onto your surface, ensuring you do not overfill it. Then, introduce your alcohol inks by dripping or dropping them onto the resin. Remember to maintain a distance between each ink drip to control the distribution of colour.

Alcohol Quest in Dead Island Riptide: Does It Exist?

You may want to see also

Combining resin and alcohol inks

Preparing the Materials

Before you begin, it is important to have all the necessary materials ready. This includes resin, a hardener, coloured alcohol inks, white alcohol ink, a silicone mold, measuring tools (such as graduated cups or syringes), mixing tools (such as sticks or plastic spreaders), safety gear (such as gloves and eye protection), and a heat gun or torch.

Mixing the Resin and Hardener

Start by accurately measuring equal amounts of resin and hardener by volume. Wear gloves during this process to ensure safety. Mix the two components thoroughly for about 3 minutes, scraping the bottom and sides of your mixing container as you go.

Pouring the Resin

After mixing, slowly pour the resin into the centre of your silicone mold. Ensure that your mold is clean, dry, and positioned on a level surface. Use a stick to guide the flow and gently fill the space, minimising the creation of air bubbles.

Adding Alcohol Inks

Once the resin is in the mold, it's time to add the alcohol inks. Start by introducing your base colour of alcohol ink. You can use pipettes to have precise control over the amount and placement of the ink. Add a few drops at a time, controlling the transparency of the colour by adjusting the amount of ink you use.

Creating Effects

To create a cloud-like effect, add a drop of white alcohol ink directly on top of the base colour. Alternate between the two colours, layering them up to six levels. You can also gently swirl the colours with a toothpick to create a marbled look, being careful not to over-mix and muddy the colours.

Curing and Demolding

Allow the resin to cure for a few hours until it feels tacky but firm. You can then add another layer of resin or alcohol ink designs to create a stunning 3D effect. After your piece has completely cured (usually after 24 hours), it's time to gently release it from the mold.

Alcohol and Rosacea: What's Safe to Drink?

You may want to see also

Pouring techniques

When applying resin to alcohol inks, there are several techniques to consider. Firstly, it is important to ensure your artwork is completely dry before applying the resin coat. If you are using a wooden panel, you may want to seal the wood with a spray or brush-on sealant to prevent bubbles.

Next, prepare your resin by mixing equal parts resin and hardener. Stir thoroughly, ensuring you scrape the bottom and sides of your mixing container. You can then pour the resin onto your artwork or into a mould. If pouring onto a panel, pour the resin directly into the centre and spread it to the edges using a plastic spreader or popsicle stick. If pouring into a mould, pour slowly and steadily, guiding the resin with a stick to avoid overfilling.

To add colour, introduce a few drops of alcohol ink directly into the resin before pouring, or drop the ink onto the resin after it has been poured. You can add multiple colours, layering them for a 3D effect. To create a cloudy effect, alternate between a base colour and white alcohol ink, layering up to six levels. You can also gently swirl the colours with a toothpick for a marbled look, but be careful not to overmix.

Finally, use a heat gun or torch to release any bubbles.

Alcohol in Semi Trucks: What's the Law?

You may want to see also

Post-pour treatment

Sealing the Alcohol Ink

Before applying the resin, it is important to seal the alcohol ink, especially if it is on paper. Yupo paper, for example, is water-resistant and will not absorb resin. However, sealing the alcohol ink with a clear-drying spray sealant like Kamar Varnish is recommended to prevent the ink from reactivating, bleeding, or smudging. Spray the varnish over the entire piece in a light, sweeping motion and allow it to dry according to the instructions on the product label.

Sealing the Wood Panel

If you are applying resin over a wood panel, sealing it beforehand is also recommended. Wood is an organic material that may contain trapped air, which can be released into the resin as bubbles. To prevent this, you can use a spray or brush-on sealant to seal the wood panel before applying the resin.

Curing and Demolding

After pouring the resin and allowing it to cure, the next step is to gently release the piece from its mold. This process is known as demolding. The curing time can vary depending on the project, but it usually takes a few hours for the resin to become firm yet tacky, and it may take up to 24 hours for the piece to fully cure.

Safety Precautions

It is important to take safety precautions when working with resin and alcohol inks. Both substances can cause skin irritation and are difficult to remove from the skin, so it is recommended to wear gloves and an apron or dedicated set of clothes. Protect your eyes from splashes and fumes with safety goggles or a full-face VOC (volatile organic compound) respiratory mask. Ensure the work area is well-ventilated to minimise the inhalation of fumes and resin particles.

Drying and Protection

Once the piece is demolded, it needs to be left to dry completely. Cover the artwork to protect it from dust particles and ensure that no one, including pets and children, has access to the uncured piece during the drying process.

By following these post-pour treatment steps, you can ensure the successful application of resin to alcohol inks, creating a glossy and vibrant work of art.

Alcohol on Testicles: Safe or Not?

You may want to see also