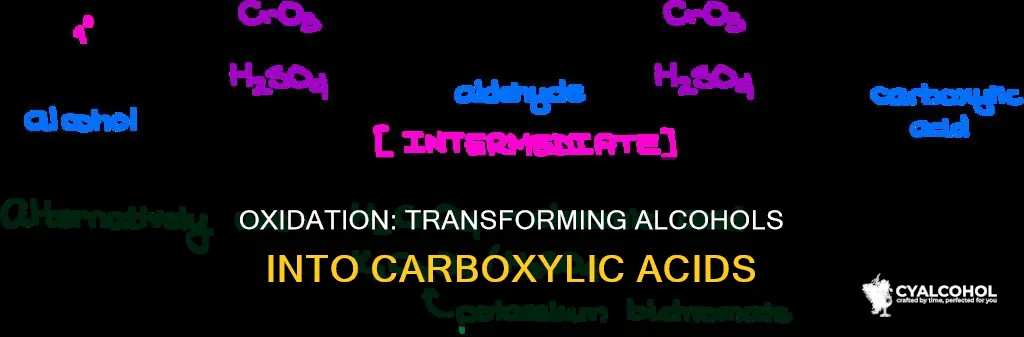

Converting an alcohol to a carboxylic acid is a common process in organic chemistry. The conversion of ethanol into ethanoic acid is a typical example of this process. The alcohol is heated under reflux with an excess of a mixture of potassium dichromate(VI) solution and dilute sulfuric acid. This process is known as oxidation, and it involves the alcohol first being converted to an aldehyde, which is then further oxidized to form the carboxylic acid. There are various methods to achieve this, including using 2-chloroanthraquinone as an organocatalyst, a cobalt pincer catalyst, or a ruthenium pincer catalyst.

| Characteristics | Values |

|---|---|

| Conversion process | Oxidation of primary alcohols or aldehydes |

| Chemical equation | 3RCH2OH + 2Cr2O72- + 16H+ → 3RCOOH + 4Cr3+ + 11H2O |

| Catalysts | Potassium dichromate(VI), sodium dichromate(VI), 2-chloroanthraquinone, TEMPO, NaOCl, NaClO2, ruthenium complex, cobalt pincer catalyst, iridium |

| Conditions | Heating under reflux, visible light irradiation, air atmosphere, alkaline water |

| Advantages | High yield, good purity, environmentally friendly, recyclable catalysts, metal-free, cheap oxidant |

| Disadvantages | Long reaction time, multiple side products, instability of certain reagents |

What You'll Learn

Using potassium dichromate(VI) solution

Converting an alcohol to a carboxylic acid can be achieved through oxidation using acidified sodium or potassium dichromate(VI) solution. This reaction can also produce aldehydes and ketones. The oxidizing agent used in these reactions is usually a solution of sodium or potassium dichromate(VI) acidified with dilute sulfuric acid. The presence of an alcohol must first be confirmed by testing for the -OH group. To do this, add a few drops of the alcohol to a test tube containing the acidified potassium dichromate(VI) solution. The tube is then warmed in a hot water bath.

For primary and secondary alcohols, the orange solution turns green. With tertiary alcohols, there is no color change. The orange color of the dichromate(VI) ions indicates the presence of chromium(VI) ions. When the alcohol is oxidized, these ions are reduced to green chromium(III) ions. The complete equation for the conversion of a primary alcohol to a carboxylic acid is:

$$3RCH_{2}OH + 2Cr_{2}O_{7}^{2-} + 16H^{+} \rightarrow 3RCOOH + 4Cr^{3+} + 11H_{2}O$$

The alcohol is heated under reflux with an excess of the oxidizing agent. This prevents any aldehyde formed from escaping before it has time to be oxidized to the carboxylic acid. An excess of the oxidizing agent must be used to ensure that there is enough for the oxidation to go all the way to the carboxylic acid.

Once the oxidation is complete, the mixture can be distilled. The aldehyde formed as the halfway product should remain in the mixture. If it is not distilled off, further refluxing with an excess of the oxidizing agent will oxidize it to a carboxylic acid.

Aretha Franklin's Dark Secrets: Alcohol and Smoking

You may want to see also

Oxidation of primary alcohols

The oxidation of primary alcohols is a widely used process in organic chemistry, often serving as a method to produce aldehydes and carboxylic acids. The oxidation reaction involves the use of acidified sodium or potassium dichromate(VI) solution, which changes from orange to green during the process. This colour change is due to the reduction of dichromate(VI) ions to chromium(III) ions.

The complete equation for the conversion of a primary alcohol to a carboxylic acid is:

$$3RCH_2OH + 2Cr_2O_7^{2-} + 16H^+ \rightarrow 3RCOOH + 4Cr^{3+} + 11H_2O$$

In this equation, R represents a hydrogen atom or a hydrocarbon group such as an alkyl group. The first stage of the reaction involves the oxidation of the primary alcohol to an aldehyde, followed by further oxidation to the carboxylic acid. This two-step process is crucial to ensure the successful conversion of the primary alcohol.

To facilitate the reaction, the primary alcohol is heated under reflux with an excess mixture of potassium dichromate(VI) solution and dilute sulfuric acid. Heating under reflux involves using a flask with a vertically placed condenser, preventing the escape of any aldehyde formed before it can be oxidised to the carboxylic acid. Additionally, an excess of the oxidising agent is used to ensure sufficient oxidation to the carboxylic acid.

There are alternative methods to achieve the oxidation of primary alcohols. One such method involves a dehydrogenative reaction in the presence of hydroxide and a ruthenium complex catalyst, specifically [RuCl2(IPr)(p-cymene)]. This reaction allows for the conversion of various benzylic and saturated aliphatic alcohols with halide and (thio)ether substituents. Another approach is a photooxidation process utilising 2-chloroanthraquinone as an organocatalyst under visible light irradiation in an air atmosphere. This method offers good yields and the ability to recycle the catalytic system for multiple runs.

Ethyl Alcohol's Flammability: A Chemical Property?

You may want to see also

Metal-free oxidation

The oxidation of primary alcohols to carboxylic acids is a fundamental transformation in organic synthesis. However, many of the available methods for this conversion involve the use of toxic and environmentally unfriendly metal-based reagents and catalysts.

A recent publication by W.-Y. Tan and colleagues in 2021 describes a metal-free, chemoselective oxidation of primary alcohols and aldehydes to the corresponding carboxylic acids. The method employs cheap 1-hydroxycyclohexyl phenyl ketone as the oxidant and features an easy-to-handle procedure, high isolated yields, and excellent functional group tolerance, even in the presence of vulnerable secondary alcohols and tert-butanesulfinamides.

Another metal-free approach involves an aerobic photooxidative cleavage of vicinal diols using 2-chloroanthraquinone as a catalyst and photoirradiation with a high-pressure mercury lamp. This method, reported by Y. Matsusaki and colleagues in 2012, is atom-economical and environmentally friendly, as it uses molecular oxygen as the terminal oxidant.

A third metal-free option is a two-step, one-pot protocol developed by M. Shibuya and co-workers in 2012. This procedure uses TEMPO/NaOCl followed by treatment with NaClO2 to afford the desired carboxylic acid in high yield and good purity. This method is compatible with a wide range of functional groups, including electron-rich aromatic rings, acid-labile isopropylidene ketal, and glycosidic linkages.

In summary, there are several effective metal-free oxidation methods available for converting primary alcohols to carboxylic acids. These methods offer advantages in terms of ease of handling, high yields, functional group tolerance, and environmental friendliness.

Quitting Alcohol: Cold Turkey or Slowly?

You may want to see also

Using cobalt pincer catalyst

Cobalt is a versatile and abundant transition metal that has been used as a catalyst in the hydrogenation of carboxylic acids to alcohols. The hydrogenation of carboxylic acids is an important reaction in chemistry, particularly for the pharmaceutical and fine-chemical industries, as well as for biomass conversion.

The hydrogenation of carboxylic acids to alcohols using a cobalt catalyst has been demonstrated in several studies. For example, Gao et al. explored the hydrogenation of different aromatic carboxylic acids, including furoic, benzoic, and functionalized benzoic acids, using a cobalt-MOF (metal-organic framework) derived catalyst. The authors found that the use of this cobalt catalyst resulted in the formation of fully saturated alcohols.

In another study, Cao et al. investigated the effect of incorporating nickel into a rhenium-based catalyst for the hydrogenation of carboxylic acids. They found that the NiRe/SBA-15 catalyst exhibited superior performance, with a high rate of H2 activation and efficient fatty acid adsorption on the catalyst surface. This resulted in high conversions and selectivities for the corresponding alcohols.

Cobalt has also been used as a catalyst in combination with other metals or materials to enhance its catalytic activity. For example, cobalt supported on hydroxyapatite (Co/HAP) was found to furnish a 100% conversion and a 95% yield of stearyl alcohol from stearic acid. Additionally, cobalt dihydrogen complexes have been used in the catalytic hydrogenation of carbon dioxide and bicarbonates, demonstrating the versatility of cobalt catalysts in various reactions.

Furthermore, cobalt pincer complexes have been employed in the hydrogenation of carboxylic acids. Pincer complexes are a type of ligand architecture that can stabilize and enhance the reactivity of the metal center. For instance, an iron pincer complex has been used in the selective hydrogenation of trifluoroacetic esters to alcohols. Similarly, ruthenium pincer complexes have been utilized in the dehydrogenation of alcohols and the hydrogenation of esters, demonstrating the versatility of pincer complexes with different metal centers.

In summary, cobalt catalysts, including cobalt pincer complexes, have been successfully employed in the hydrogenation of carboxylic acids to alcohols. These catalysts offer advantages such as versatility, stability, and high selectivity, making them promising alternatives to traditional noble-metal catalysts.

Ear Cleaning: Vinegar and Alcohol Frequency

You may want to see also

Conversion to carboxylic acid salts

Carboxylic acids can be synthesized by the oxidation of primary alcohols or aldehydes. Primary alcohols are oxidized to carboxylic acids in two stages: first to an aldehyde and then to the acid. A dehydrogenative reaction of primary alcohols in the presence of hydroxide and a ruthenium complex as a catalyst provides carboxylic acids. The use of toluene enables a simple product isolation by precipitation and extraction.

A facile and mild photooxidation of alcohols gives carboxylic acids and ketones using easily handled 2-chloroanthraquinone as an organocatalyst under visible light irradiation in an air atmosphere. An aerobic photooxidative cleavage of vicinal diols yields carboxylic acids using 2-chloroanthraquinone in the presence of photoirradiation with a high-pressure mercury lamp. This is a metal-free reaction in which molecular oxygen is used as the terminal oxidant.

A smooth, organocatalytic one-pot oxidative cleavage of terminal 1,2-diols to one-carbon-unit-shorter carboxylic acids is catalyzed by 1-Me-AZADO in the presence of a catalytic amount of NaOCl and NaClO2 under mild conditions. A broad range of substrates, including carbohydrates and N-protected amino diols, were converted without epimerization.

The conversion of ethanol into ethanoic acid is a typical example of the synthesis of carboxylic acid from primary alcohols. The alcohol is heated under reflux with an excess of a mixture of potassium dichromate(VI) solution and dilute sulfuric acid. Heating under reflux prevents any aldehyde formed from escaping before it has time to be oxidized to the carboxylic acid. Using an excess of the oxidizing agent ensures that there is enough oxidizing agent present for the oxidation to go all the way to the carboxylic acid. When oxidation is complete, the mixture can be distilled.

Carboxylate salts can be produced from wastes, such as paper fines, municipal solid wastes, sewage sludge, and industrial biosludge. Using a proprietary technology, the wastes are first treated with lime to enhance reactivity. Then they are converted to calcium carboxylate salts using a mixed culture of microorganisms derived from cattle rumen or anaerobic waste treatment facilities. The calcium carboxylate salts are concentrated and reacted with a low-molecular-weight tertiary amine and carbon dioxide to precipitate calcium carbonate.

Alcohol's Quick Trip to Your Bloodstream

You may want to see also

Frequently asked questions

The general process involves the oxidation of primary alcohols and aldehydes.

Examples include the use of:

- TEMPO/NaOCl followed by NaClO2

- Ruthenium pincer with basic water

- Cobalt pincer catalyst (NNNHtBuCoBr2)

- 2-chloroanthraquinone with visible light irradiation

- 1-hydroxycyclohexyl phenyl ketone

The equation is:

3RCH_2OH + 2Cr_2O_7^2- + 16H^+ → 3RCOOH + 4Cr^3+ + 11H_2O